How a Superior Inventory Control System can impact your Supply Chain

Understanding the impact of Inventory Control is key to your business’ operation. In the post Inventory Control Solutions need a focused perspective, we discussed why you should practice Inventory Control. A top-notch inventory control system will deliver reduced overhead costs and increased throughput. You will not achieve these reductions and savings overnight. A smooth transition and an immediate Return on Investment (ROI) are rarely the cases. You need to understand how managing the change that comes with a quality inventory control system is key to accomplishing the desired results in a shorter timeframe.

The Impact of Change Management on Inventory Control

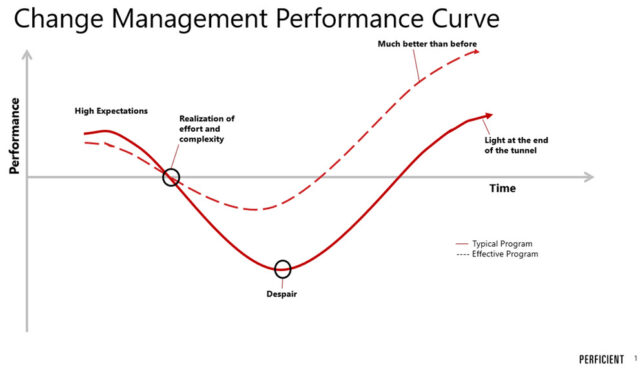

In understanding this change as it relates to performance, one must understand the emotional and psychological changes that occur as a new system for management is put into place. Understanding Change Management is critical to minimizing the negative impact of changing the inventory control processes when implementing a top-tier system. The graph below helps illustrate this impact over time:

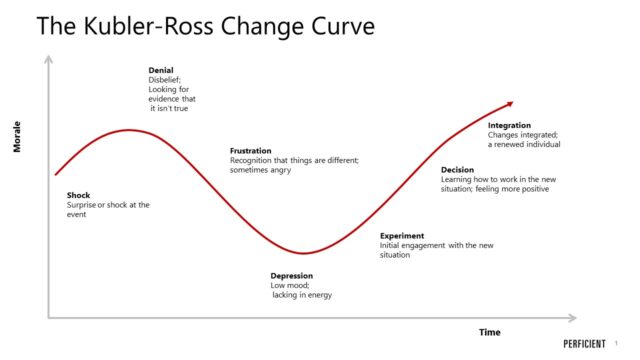

The workforce encounters many different emotional states as part of this change. The Kubler-Ross change curve depicts this effect on the morale of the workforce over time.

In both cases, there is a dip and a loss in productivity/morale. There’s an upturn as adjustments are made. Morale then continues to improve. For many pursuits, the journey to the “Light at the end of the tunnel” can be long and tiresome. Change Management is designed to help you reduce the dip. Effectively using Change Management will help you navigate the pitfalls and minimize the emotional cost. This will get you to the goal sooner. If you would like to know more about Organization Change Management, I would recommend that you take a look at the Perficient Guide on Best Practices.

Superior System Quality and the Impact on the Inventory Control

In this section, we will discuss the impacts of a quality inventory control system on its neighboring processes. The three main focuses will be on:

- Manufacturing

- Distribution

- Transportation logistics and Yard Management

Manufacturing

Inventory control for manufacturing is critical to keep production going. In a manufacturing environment, time is the most critical constraint. A production line can only produce so many items (or widgets) per hour. When multiplied by the number of working hours in a year, you arrive at a gross total number of widgets that can be produced. Every second of equipment or process downtime results in a reduction in the number of widgets that can be produced.

With time being the key constraint, material preparation is important. Precision is key for this process. Depending on the flow, material movement can follow different philosophies. These philosophies can also align with inventory replenishment strategies. Examples are as follows:

- Constant Production Line – Kanban Replenishment of materials to keep the production line going. Management of the back-up material slot is critical to keep production going. Inventory management will treat the consumption location of material as consumed at the point of movement. Inventory tracking is based on a rate of consumption over time and anticipated demand.

- Kitting/Pre-assembly – Assemble material packages on demand and deliver them to a hand-off station or to the production area. Inventory management is based on a forecasted/task assignment on an as-needed basis.

Impact of Inventory Control Discipline in Manufacturing

Communicating, policing, and enforcing inventory discipline are extremely vital in manufacturing. Any deviation from production planning to material execution can lead to excessive downtime and loss of production and potential revenue. A mentor of mine has often said, “If you need to track, you’ve got to transact.” This means that to properly and effectively manage inventory in any location, you must transact and account for every movement. Otherwise, the material will get lost. Once lost, it will not be properly transacted.

Examples of Poor Inventory Discipline in the Manufacturing environment

- Physical movement and consumption of material with no system registration of the transaction(s)

- Physically grabbing the wrong grouping of material to issue to production

- Same Finished Good Production Output

- Looking for the components instead of the Kitted grouping of materials associated with the job/batch

- Cannibalizing a later scheduled job/batch for one or two items needed for a current job/batch without proper system updates

- Non-efficient storage of material

- The oldest material is hardest to reach

- Locator addresses are hard to read

- Locator spaces are too cumbersome to manage

Ideas on how to overcome Poor Inventory Discipline in the Distribution environment

- Physical movement and consumption of goods with no system registration of the transaction(s)

- Additional QC checks to verify that everything has been properly processed in the system.

- Are all pick lines in a pickable status?

- Supervisor review of the process and execution

- Additional reporting

- Additional programmed stops to prevent the improper consumption of material if there are lines in an improper status

- User Training

- Verify all tasks are complete at the end of each shipment, shift, role, etc.

- Proper Communication of completed transactions

- Verbal communication

- Paper Slip delivered to the correct container

- Additional QC checks to verify that everything has been properly processed in the system.

- Disciplined movement of Materials

- Do not deviate from the suggested picking area unless there is an exception to the rule

- Do not leave an area until all unpicked goods are returned

- If the goods are to remain in their new location, make sure to transact the inventory movement before leaving that location

Distribution

Inventory control for distribution is critical for both internal and external operations. A distribution center is a warehouse facility that receives and ships goods (usually Finished Goods or FG). This can be to another Distribution Center or to a Fulfillment Center. A Fulfillment Center ships goods (usually, FG) to a retail operation or directly to a customer.

A Distribution Center can also act as a Fulfillment Center. A Distribution center tends to ship goods in Case or Pallet quantities whereas a fulfillment center can also ship in smaller quantities. For use in this discussion, both will be grouped together as they are in the business of picking and distributing goods to an external entity.

KPIs

In a warehouse environment, time management and order accuracy are the most critical factors. Key Performance Indicators (KPIs) are used to track and measure these critical factors. These KPIs in a distribution center tend to be task time efficiency (TTE), inventory turns, and orders fulfilled on time in full (OTIF).

TTE and OTIF KPIs are related to inventory controls and goods storage. Higher accuracy of storage is linked to the ease of retrieval. This results in higher KPIs for both matrices. Unproductive processes will result in low KPIs. For example, inaccurately storing goods causes unproductive resource time. Consequently, exception management is a byproduct of unproductive processes.

The Inventory Turns KPI measures how many times a year a facility can sell its entire inventory. If OTIF is a high number, it should also result in a high Inventory Turn KPI. Executive Management, as well as Financial and Operations managers, use the Inventory Turns KPI to gauge the productivity of a company overall as well as the productivity of a specific site. If goods are not moving, then it is costing the company storage and inventory maintenance costs.

Impact of Inventory Control Discipline in Distribution

Just like with manufacturing, the communication and enforcement of inventory controls are also important in distribution. Any exception in the process will certainly result in the loss of revenue. For instance, in distribution, inventory accuracy is paramount to cost efficiency. To effectively manage your inventory, you must transact and track every movement. Likewise, if you don’t properly perform the transaction, the material will get lost. Consequently, lost material leads to process delays. As a result, these delays are process inefficiencies. Therefore, these inefficiencies result in delays in order processing and shipping. Below are some examples of what these inefficiencies are.

Examples of Poor Inventory Discipline in the Distribution environment and the impact on inventory control

- Physical movement and consumption of goods with no system registration of the transaction(s)

- Goods were physically loaded onto the truck, the system did not allow the transaction

- Goods were packed and shipped but never recorded

- Shrinkage of Inventory

- Incorrect identification of goods within a staging area

- Outbound Labels/Identification is poor

- More than one shipment/carrier’s goods are residing in the same area w/o proper shipment identification information

- Lack of proper housekeeping

- Incomplete movement of goods

- The pallet is moved from upper rack to floor for partial picking and never returned to its original location

- Pallet(s) or good(s) are moved to allow for access to another pallet. The moved pallets are not returned to their location.

- Improper placarding of locators causing the incorrect placement of goods

- Example 1: a rack space is 2 pallets long. The Pallet (Pallet 1) in spot 1 is in bin 01, and the pallet in spot 2 (Pallet 2) is in bin 02. You can only reach Pallet 2 by removing Pallet 1. An Order needs Pallet 2. You move Pallet 1 into the aisleway. Pallet 2 is picked. Pallet 1 is returned to bin 02 by mistake.

- Example 2: Mixed goods are stored in one location. The rack is 2 pallets wide and each pallet space is its own locator. You temporarily move the unwanted Goods to the neighboring pallet. They are never returned to their proper pallet when picking is complete.

- Incomplete movement of goods

Ideas on how to overcome Poor Inventory Discipline in the Distribution environment

- Physical movement and consumption of goods with no system registration of the transaction(s)

- Additional QC checks to verify that everything has been properly processed in the system.

- Are all order lines in a “Shippable” status?

- Supervisor review and signoff

- Additional reporting

- Additional programmed stops to prevent the improper shipment of goods if there are lines in a pending state

- Additional QC checks to verify that everything has been properly processed in the system.

- User Training

- Verify all tasks are complete at the end of each shipment, shift, role, etc.

- Ensure proper communication of completed transactions

- Verbal communication to Management

- Paper Slip delivered to the correct container

- Disciplined movement of Goods

- Do Not leave an area until all unpicked goods are returned

- If the goods are to remain in their new location, make sure to transact the inventory movement before leaving that location

Yard and Transportation Logistics

The Trailer Yard (Yard) is a storage area for Shipping Containers. The containers are loaded or unloaded when time is available for the warehouse staff. For example, many warehouses treat the yard as an extension of their warehouse. Yard Management has certainly become a required module for warehouse and inventory management. Some WMS systems have had it integrated for several years while others are just starting to branch out into it. Proper utilization of the yard will have an efficient impact on your inventory control system.

Yard Management

Facilities designate a large space for staging trailers. These trailers are for any of the following functions:

- Inbound Receipts – Trailer dropped off in the yard to be unloaded at a later time. The driver could have arrived during non-peak hours or off-hours.

- Excess Storage – Trailers are used for additional storage. Reasons:

- Overflow: Not enough space in the warehouse, so they are using the trailer as an additional storage facility

- Special Storage requirements: Special Material may need to be physically separated from the rest of the material on-hand. Reactivity or temperature control requirements are the main requirements. Other storage requirements may be due to government policy (ex. in the US, ITAR compliance requires complete segregation for material storage).

- In transit: Material needs to be moved between buildings. The receiving building is not ready to process the inbound materials.

- Outbound – Material has been picked/packed and is ready to ship except for the following:

- Before the Pickup and Dispatch of the trailer to a truck, additional staging needs to be performed. Examples could include sterilization of the goods on the truck

- Pickup Delay – The trailer is loaded. You can ship the product. However, the cab of the truck has not arrived.

- Cross-docking – The trailer arrives to have its contents consolidated. There’s no need to bring these goods into the warehouse. The shipment of these goods is quick. There’s no need for additional material handling. This can occur one of three ways:

- Additional goods are added to the trailer.

- The goods are transferred from the original trailer directly to another trailer.

- The goods are immediately placed into a staging lane to be shipped out when the carrier arrives.

Conclusion

A quality Inventory Control System can have a positive impact on your business. However, as the need for attention to detail increases, so does the need for discipline. Top-tier systems certainly require lots of discipline from the staff and workforce. They will see more value in the system when there’s a decrease in “non-value” activities in their routines. Also, those key activities will reduce tasks and inventory count audits. You will also notice an increase in speed, efficiency, and accuracy. Above all, these positives will lead to a finely tuned warehouse. The key impact that everyone is looking for is an efficiently operating warehouse. This will also lead to ideal product turnover times and a reduction in inventory carrying costs. Just remember that the overall goal is lots of productivity. Above all, keep your eye on the prize and try your best to avoid the pitfalls.