Manufacturing is the process of making an item to sell. Within manufacturing, there are several different manufacturing types and sub-types. So, how do you know what type of manufacturing environment your company is using? In this post, we will review the three main manufacturing types and the key terminology that goes with each one.

The three main manufacturing types are:

- Discrete

- Process

- Project

Manufacturing Type: Discrete (WIP)

Discrete Manufacturing is like buying furniture from IKEA. Several independent pieces come together to make the final item. These pieces are made at the same time. This optimizes the overall manufacturing time. Using a simple table as an example. There are three main components; the tabletop, the table legs, and the fastening hardware. The process to make each piece can start at any moment in time. You could start making the legs days or hours before you start making the tabletop. At the end of the manufacturing process, all of these parts come together. From there, there are two choices. Bundle the parts into a box or assemble the parts into a fully-built unit.

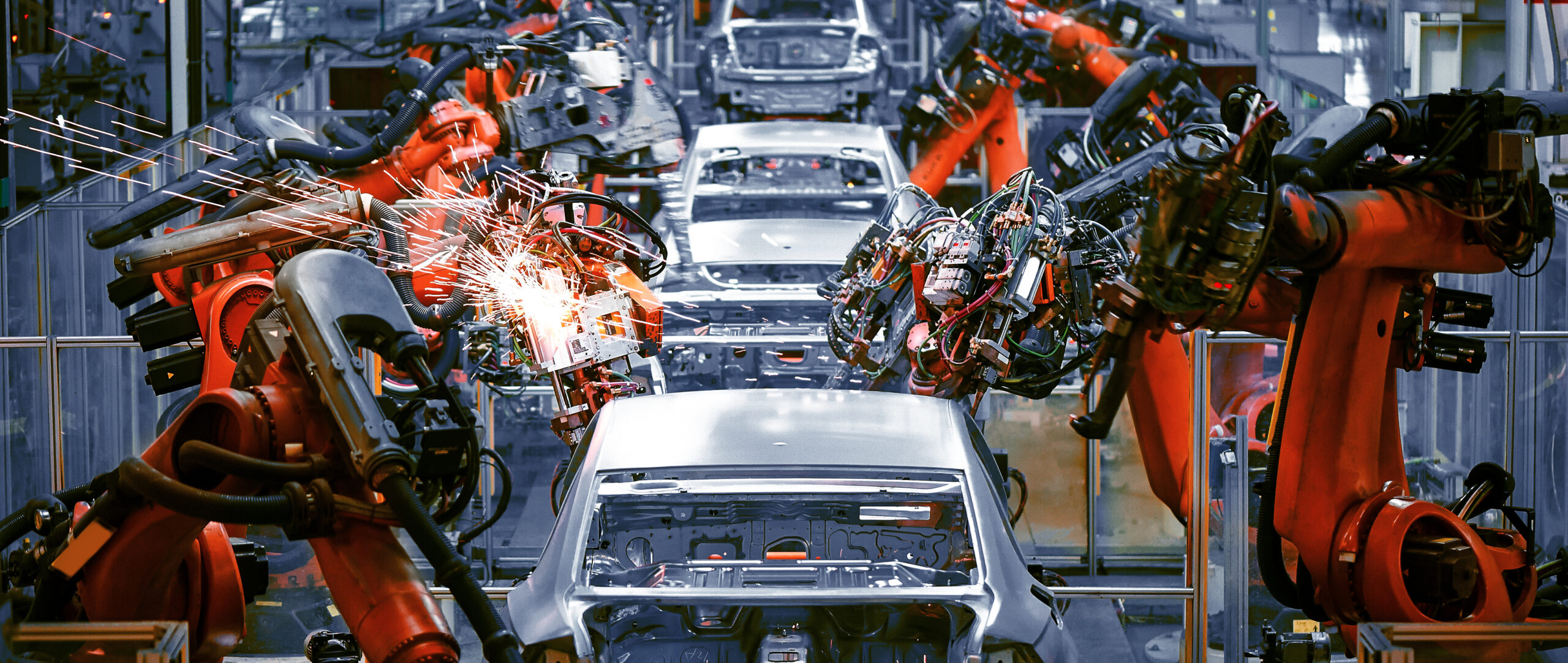

Flow Manufacturing

Flow Manufacturing is an advanced form of discrete manufacturing. The process is the same, but instead of building to a forecast, you are building to demand. The process has lower overall costs. The dedicated production lines and mass production means that optimal costs have been achieved. Think of flow manufacturing as something similar to the building of a car on the manufacturing line.

Discrete Manufacturing Terminology

Terms most commonly heard in a Discrete Manufacturing Environment. I have broken them down into two categories. The Process (terms associated with the job structure) and the Output (terms associated with the physical material).

Process Terminology

Bill of Material (BOM) – The list of materials needed for a WIP Job to build an assembly. Many cloud ERPs prefer to utilize the term “structure” instead of BOM. This is for safety and to reduce people mistakenly thinking the person is referring to an actual Bomb.

Component – The listed material in a Structure/BOM.

Exploding BOM – The act of viewing all levels of an Indented BOM. A complete view of all materials needed to make an assembly.

Indented BOM – A Multi-level or Master bill of materials. The bill includes all of the materials needed to build the sub-assemblies as well as the main item. Also known as a Multi-level BOM.

Operation Step- A singular step in the WIP Job to create the Assembly. Attaching legs to a table is an operation step.

Routing – The ordering of Operation Steps to be followed to complete the assembly.

WIP Job – The process of building one assembly in discrete manufacturing is a WIP Job. WIP is short for Work In Process.

Output Terminology

Assembly – The desired completed product of a Work in Process (WIP) Job.

By-product – An unplanned secondary end unit from a WIP Job. The manufacturing cost of the second item is minimal (close to zero). An example would be coconut water. Chopped up fresh coconuts are the main product. Also, the water found in the coconut is sold.

Co-product – A planned secondary end-unit from an assembly. This unit carries its own cost as part of the production. An example of this would be processing a pig to make a ham. The Ham may be the main item, but the other items are also planned as part of the process.

Sub-Assembly – A WIP Job to build a component for the main assembly. Making the table legs for a table is a sub-assembly.

Manufacturing Type: Process (Batch Manufacturing)

Process Manufacturing is like baking cookies. Several ingredients, but there’s only one true way to make the cookies and you can’t go out of order or make parts of the cookie in parallel. The mix is forever impacted once an ingredient has been added. Optimal batch production is the goal. This is where the formula, size, and cost result in the greatest revenue. A process batch is a name for this type of manufacturing job. Going back to the cookie analogy, it’s because we are making a batch of cookies.

Process Manufacturing Terminology

The terms most commonly found in a Process Manufacturing environment:

Batch – The name for a Process Manufacturing job to create one lot of an item in Process Manufacturing.

By-product – An unplanned secondary item created in the production process. The manufacturing cost of the second item is minimal (close to zero). For example, Molasses is a byproduct of refining sugar.

Co-product – A planned secondary item from a batch. This item carries its own cost as part of the production. A classic example of this would be doughnut holes. The traditional doughnut is the main item. However, the excess dough at the end of the production run makes the doughnut holes.

Formula – The list of ingredients needed for a specific Recipe.

Ingredients – The list of raw and intermediate materials needed to produce a batch.

Lot – A grouping of items that were completed in the same batch. A dozen cookies baking on the same cooking tray would be one lot. Quality tracking is the main reason for lot assignment.

Recipe – The list of steps and formulas and ingredients to produce a batch of product.

Manufacturing Type: Project

Manufacturing Type: Project

Project Manufacturing is a blend of project management and manufacturing. It is like remodeling your home. 100% custom and the plans, measurements, and materials won’t likely be used for another home remodeling project. Every project is unique to itself. The only repeatable deliverable here is the process.

Contract Manufacturing

The creation of the component by subcontracting a portion of the process to another manufacturer is Contract Manufacturing. The subcontractor is not directly tied to the outcome of the project. Contract manufacturing occurs with any of the three types of manufacturing. It is more prevalent in project manufacturing. Outside Processing is a form of contract manufacturing. Think of this as NASA commissioning Tesla to build solar batteries for their next rover vehicle. The battery is a key component, but the success of the rover project meeting its timeline and budget will not impact Tesla’s overall business.

Project Manufacturing Terminology

The terms most commonly found in a Project Manufacturing environment are:

Engineering Change Notice (ECN) – An official notice of an approved change. These notifications are used along with an ECO when communicating with Contract Manufacturers. This is to ensure that the contract manufacturer is aware of the required change.

Engineering Change Order (ECO) – A document that outlines a change in the overall design of the project. Changes within a specific manufacturing task also require an ECO.

Manufacturing Work Instructions (MWI) – Directions and additional information on how to perform a manufacturing task.

Milestones – An action or event marking a significant change or stage in development. In some projects, billing and payment occur with the successful achievement of a milestone. Milestones are events like completion of product design, the product is made, the product is delivered, and the product is approved by the customer.

Phase – The grouping of tasks to accomplish a subset of the project.

Work Package – A grouping of Work Instructions that are to be completed during the current phase of the project.

Conclusion – What Manufacturing Type is your company using?

Understanding what type of manufacturing that your company is using is important. Knowing the terminology will help you find common ground. Once you can speak the language, you can quickly understand what processes are being utilized. This will also help you with what additional tools are available for improvement.